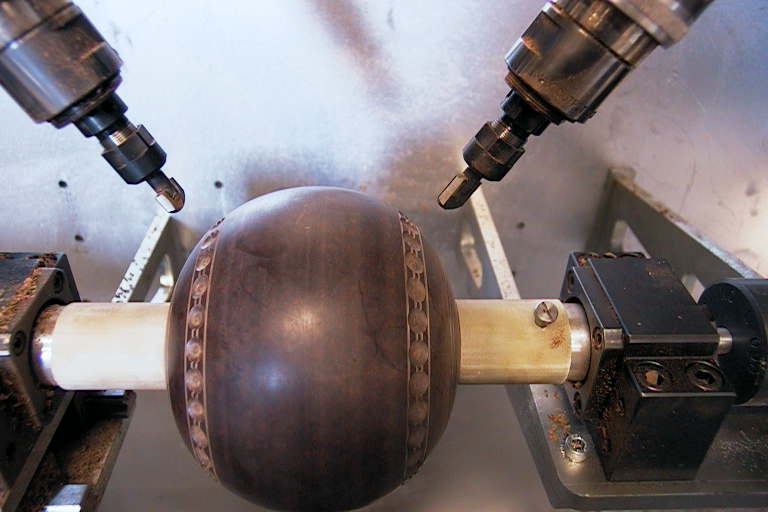

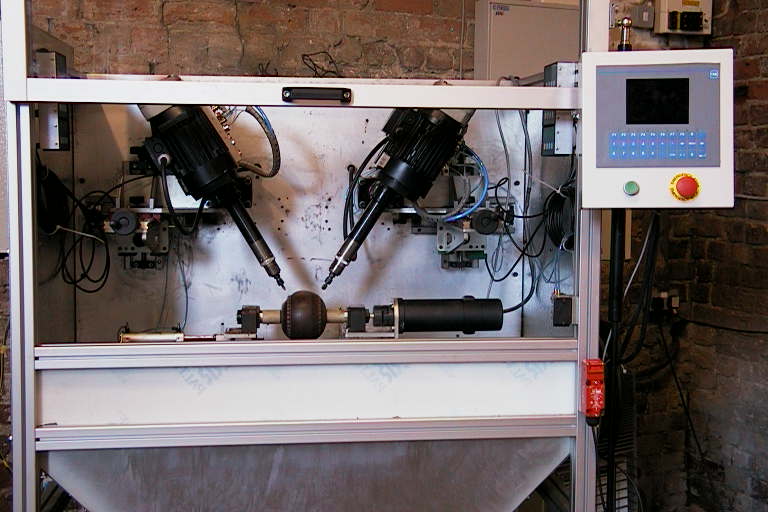

Custom Designed Machine for Manufacturing Bowling Balls.

Courtesy of Bespoke Machines

Our client is a specialist manufacturer of custom made machines. Having supplied machines for different industries, our client won a contract to build a machine to make the decorative grooves and marks for bowling balls.

The clients specification called for the ability to manufacture 50 balls per hour with a variety of marks and patterns. Bespoke Machines Ltd. used a 1 axis TRM motion controller with MAP software, a 1.2 Nm servomotor with 1000 ppr encoderm, a proximity sensor for home position and a custom TRM electrical cabinet. All wiring between the electrical cabinet and controller was pre-made at TRM's facilities allowing our customer to build a machine to meet and exceed his clients requirements. The machine is now producing 60 bowling balls per hour and is capable of making many more patterns than before. |  | |

TRM supplied all the electrical controls and motor mentioned above when the machine was 80% built, since all the wiring was pre-made it was quick to install and ready to start the initial tests soon after delivery. Today the machine is manufacturing bowling balls with more patterns and better quality than ever and still remain competitive with labour costs down and greater production. In order to make the grooves, marks and patterns, the servomotor rotates the bowling ball with high accuracy. Then, using the digital outputs, the controller turns the tool motors On and Off. Using the controller’s capability for storing up to 100 user programs, different programs are created for making different patterns as shown on the photo above. Download this Case Study as PDF | ||

|  |  |

SOFTWAREThe controller was programmed using the Motion Application Programme ‘MAP’. ‘MAP’ has been used in a vast variety of machines and applications giving the user a greater control of costs, saving money and time on software development.

| MOTIONPoint to Point move:

| TYPICAL APPLICATIONS

|

Items Provided By TRM for this Application:

Professional Motion Controller

1 off 3 Axis stand alone motion controller with keypad and colour screen.

Electrical Cabinet

24 Volts for the motion controller and the power supply for the DC servo amplifiers to run the motors using an external transformer. Screw connectors are used for connecting the Inputs/Outputs for a fast connection, On-board filtering of power supplies and signals.

Servomotor

1 off Servomotor rated at 1.2 Nm and at 60 V

DC Servo-Amplifier

1 off compact current mode amplifier capable of driving brushed DC Servo motors continuously at up to 100 volts and up to 5, 10 or 20 amps depending on the model

Encoder

1 off Rotary Encoder with 1000 ppr

Sensors

1 off Inductive Proximity sensor for home position