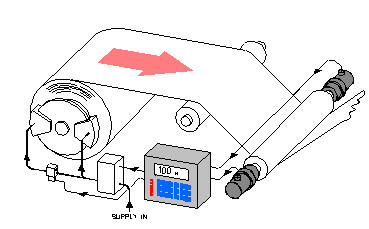

Semi-Custom Tension Control System.

TRM was contacted by CMC to develop a control system that had inputs for a variety of strain gauges and also had software easily setup and suitable for tension control applications. Based on one of TRM's standard controllers we designed an interface card that attached to the rear of the controller that provided all the supplies and analogue conditioning needed for this application. Also included on the board were spring clamp connectors making installation a simple task.

The software was written specifically for this task and provided a large readout of the read tension so that it could be seen from a distance. As there are many different ways a tension controller can be used there is a setup menu where the installer can select the type of tension (Unwind, Intermediate and Winder), single or multiple load cells, encoder feedback, operates motor, brake or clutch and many other features.

The overlay was also customised so that the key labels suited the industry sector, e.g. 'Tension Off', 'Set Taper', 'Low Tension' and others. This again made the user interface more intuitive which when combined with the software makes this a very accurate yet simple controller to use.

CMC is now owned by the Lincon Electric group.

What Is Web Tension?

Tension is the effect produced when forces pull in opposition to each other. Web tension in the converting industry is this same force in very thin flexible materials and is that force pulling the material from the unwind, stretching the material and transporting it through the process and winding the finished product on to reels. Tension force applies to paper, plastic film, textiles, foils such as aluminium, copper, thin steel and other metals, wire, cable, filaments and fibres; in fact all flexible materials used for converting.

Is Web Tension Important?

Web tension is the single most important, but often invisible, factor that affects the successful operation of converting machines. If the web runs slack due to insufficient tension it will wander, wrinkle and probably snatch. If the tension is excessive, stretching, creasing and possible web breaks will occur. In both cases poor quality will be produced and the machine will not be efficient. Automatic control is necessary because all reels change diameter as they are processed, machine speed is changed and outside disturbances occur. These disturbances change the tension if no action is taken. Some causes of outside disturbances are: Eccentric cores, bent shafts and out of round reels; Unnecessary speed changes; Unwinding of blocked reels or other wound-in defects; Oven temperature changes; Tight and slack edges and poor guiding; Splices and joints.

Different Tensions In Different Sections Of The Machine

Most reel fed converting machines have several sections or zones - unwind; one or more process or intermediate sections, such as coating, printing, drying, laminating, or other operation; and finally a winder or sheeter. This final section is perhaps the most critical part of the machine because here the material has its highest added value. For best product quality and overall machine performance each of these different sections may require different values of web tension depending on the process and material.

Unwind Section

In reel fed machines web tension is created by two types of actuators,- brakes or motors. Brakes generate torque either by friction or electromagnetically. The torque is regulated pneumatically or electrically. The torque is applied to the reel and hence the web through the reel centre.

Process Or Intermediate Section

The tension level in this section of the machine depends on the particular process and the material used. The principle function of an intermediate section is to isolate the process tension from the unwind tension or the winding tension, meaning that the tension on one side must not affect the tension on the other.

Winder Section

Winding tension is the most critical as here the material has its highest added value and the reels need to be wound correctly for onward transport or further processing.

Keeping The Tension Constant

There are four methods of keeping the tension constant: Reel Diameter Followers, Predictive System, Dancers, Tension Transducers (Load Cells).